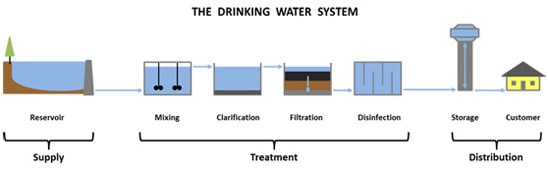

A municipality came to ACES with a freshwater system in need of updating. The existing control systems of the plant were showing their age, with slow and unreliable communication and many manually-performed operations. ACES installed new PLCs, cabinetry, VFDs, Ethernet, radios and a Wonderware SCADA system to connect it all. This major system upgrade enables near-instantaneous communication flowing to and from the outlying stations.

The freshwater system includes the main plant and an SPR with a settling basin, which is run by a PLC. Water exits the basin through a pipe into which two feeders flow: a carbon feeder to remove taste and odor, and a lime feeder to regulate the PH balance — both controlled by remote racks off of the PLC. From there the water enters the sand filters. There are also nine remote sites, including three towers, three local lakes, a storage tank and a booster to a neighboring city, each linked in through upgraded PLCs and radio transmitters with battery backups.

Crystal Clear Communications

Signals from each substation surge in to the central plant, keeping operators current on the status of essentials like water pressure and flow. In turn, the central station pours out instructions like telling an outlying pump to start up, or a valve to open or close.

MDS iNET-II Ethernet radios make for speedy transmissions, replacing sluggish serial communications radios — which took as long as 15 minutes to provide an operator with confirmation after relaying a command to, say, turn on a pump. Late-model frequency hopping and a spread spectrum protocol ensure reliability.

In addition, wired connections were upgraded to Ethernet to eliminate the error and complexity inherent in analog wiring. Now information streams via Ethernet to new PLCs, remote racks for the SPR filter, lime feeder, carbon feeder, final sand filters and the radio system. Chlorine and ammonium filters are hard wired to the PLC.

Clever Valves

Signals to and from valves throughout the system got a major upgrade with the switch to Wonderware. For example, all the valves and pumps involved in the backwash cycle for the four sand filters are now completely automated, as compared to manual operation with the old system. This provides consistency and saves time, water and energy. Adding to the increased efficiency was the consolidation of four small individual PLCs and screens into a single screen in the filter room — and the sand filters can also be are controlled from the central station.

In the three water towers, a valve on the intake pipe will close when a sensor indicates the tower is full before it is filled past the overflow level, and a check valve closes if pressure to the tank exceeds established limits.

The old system gave the operators no indication if a valve was in the open or closed state. Now, if they signal the valve to open and it doesn’t, an alarm will sound or a “failed to open” alert will appear onscreen.

Wonderware times how long it takes a valve to open or close, in fractions of a second, and monitors this action. If a valve slips in performance the system will call up a warning on the screen, providing an early warning system that allows time for preventive maintenance. In addition, maintenance minders can be set to, for example, ping operators to grease the pumps monthly or replace the seals annually, with actions and timetables determined by the customer.

More Upgrade Perks

Not only can the entire plant now be controlled by one operator at one station, but the network can be accessed remotely via modem from anywhere in the world by ACES or another contractor for servicing and upgrades. This lowers transportation time and cost to the customer.

Historical data is highly compressed and saved as an easy-to-access SQL database, and is locally duplicated on a server. Previously data was saved in a fairly unreadable and inaccessible format.

VFDs on pumps throughout the plant provide efficiency by modulating the power to each individual pump. For instance, if the customer needs only 40psi on a line but their pump outputs 80psi, the VFD lowers current — and operating costs — accordingly.

Sparkling communication, automation, consolidation and ease of maintenance are just a few of the features of this freshwater plant upgrade, leading to greater control and peace of mind — and fewer dollars down the drain for this customer. If you have a water system in need of freshening, maintenance, or upgrades, give ACES a call.