One of ACES’s customers is a company that processes wastewater using advanced technology, removing contaminants and returning 100% reclaimed water. They called ACES to retrofit a hydraulically-powered filter press that had originally been integrated into an automated paint filtration system complex enough to necessitate the use of three large control cabinets to house all of the controls.

The filter press was purchased and re-tasked by the wastewater treatment facility as a simple water filtration system. In its new capacity the filter press didn’t need of all of the controls in the three large cabinets. Many of ACES’s projects involve programming PLCs for more automation, but in this case the customer found that a smaller, less complicated control system was in order.

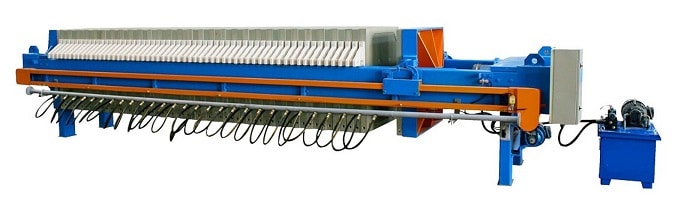

ACES removed the old control cabinets and built a brand new streamlined one dedicated to controlling the filter press, which consists of a two-horsepower pump that forces water through a series of vertical filter plates. When pressure reaches 75 psi the press automatically stops and signals the operator to open the press, access the contaminate “cake” that has formed on the filter, and scrape it into the catch basin. He then pushes a button to restart the whole cycle.

The press is fairly large and can run unattended for a considerable amount of time before it’s ready for the scrape down. For the customer this semi-automated process is preferable to the previous fully automated system with its tangle of three separate control cabinets. Now the process of decontaminating the wastewater is as pure and simple as the clean water that is the final product.

ACES specializes in customization to suit a customer’s needs, however unique. What project can we quote for you today? Give us a call.